Equipment Remote Maintenance

Realize remote operation and maintenance of equipment distributed around the world

Device remote configuration

Device remote debugging

Equipment remote maintenance

Remote upload and download

Equipment remote monitoring

Preventive maintenance

With the development of Internet of Things technology and cloud platform technology, more and more users want to be able to remotely diagnose and maintain products sold or held through the Internet, which can reduce the time and cost of maintenance engineers to the site, not only It saves a lot of manpower and material costs, and at the same time, it can provide customers with more efficient and high-quality services and reduce customer losses. Therefore, remote diagnosis and remote maintenance have become urgent problems for equipment manufacturers.

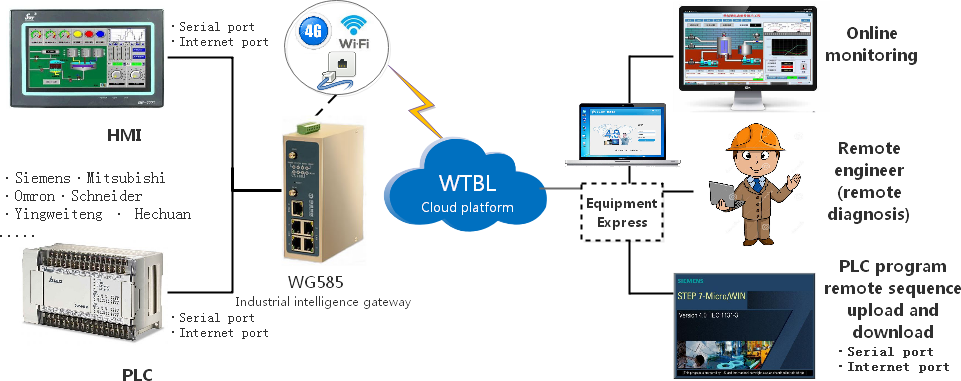

WideIOT's equipment remote operation and maintenance solution can assist equipment manufacturers and project operators to realize functions such as equipment remote management, remote diagnosis and remote upload and download of programs; at the same time, it can realize preventive maintenance and life cycle prediction through big data analysis and other advanced applications.

1. Build a safe pipeline leading to the field equipment to realize the maintenance work such as remote monitoring, debugging and program uploading and downloading of PLC.

2. Real-time monitoring, analysis and early warning of key indicators of equipment through the big data cloud platform can achieve preventive maintenance.

3. Centrally manage equipment scattered around the world through the data platform, and realize value-added services such as R&D innovation, business innovation, and after-sales innovation through data utilization.

Internet of Everything

Intelligent Collection

Edge Computing

Cloud Application

Device remote configuration

Remote configuration of distributed devices

Device remote debugging

Build a remote data channel to remotely debug the device

Equipment remote maintenance

Combined with the equipment maintenance express line, remote maintenance is carried out

Remote upload and download programs

Realize PLC remote upload and download program

Equipment remote monitoring

Realize remote monitoring of equipment, real-time monitoring

Equipment preventive maintenance

Monitor and analyze key indicators of equipment, preventative maintenance, reduce operating costs and improve service quality

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Wtunnel

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.

click to view detail>>

-

WCloud

WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.

click to view detail>>

-

WLink

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>> WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>>

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>> WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>>

WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>> WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

Go Top

Go Top